The automated product management system designed ad hoc for the hospital pharmacy of the Schiavonia Hospital was installed to allow a better management of references and related data, as well as to free the staff from repetitive tasks.

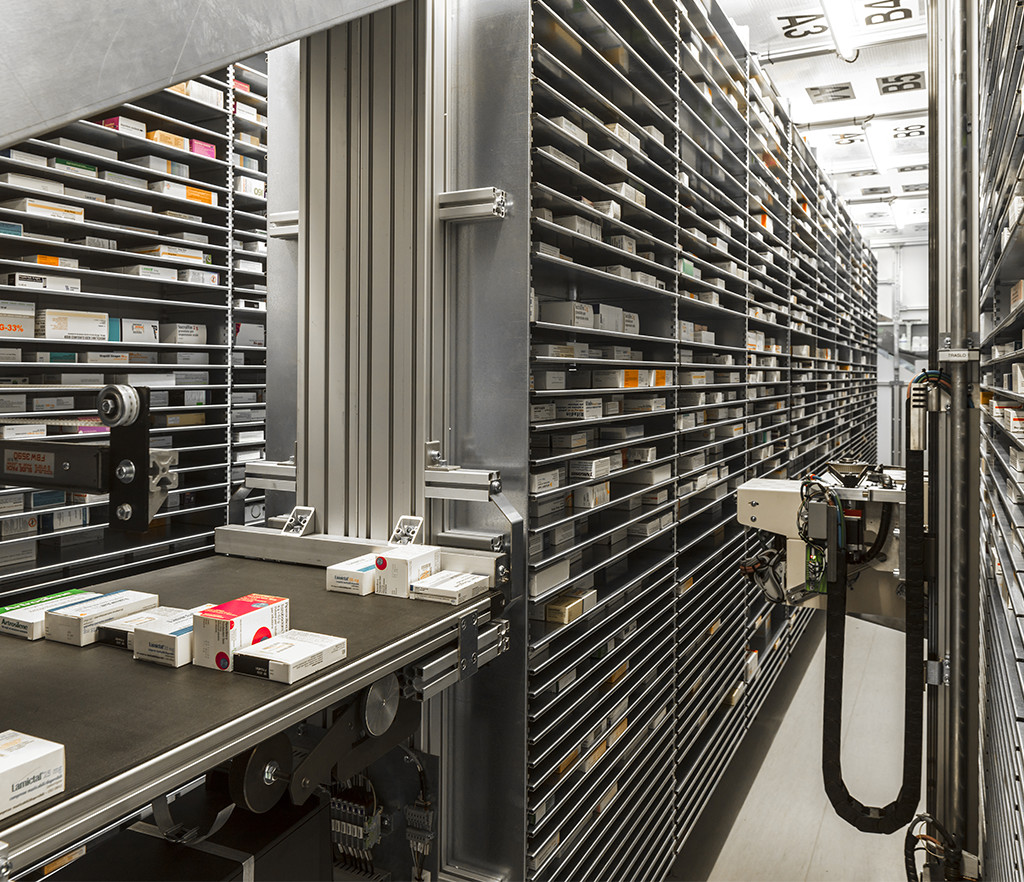

Overall, the robot manages 46,000 packages of medicines, stored in controlled environments for temperature and humidity, inside two separate robotic units, each dedicated to a different type of product. They contain 85% of hospital stocks, while the remaining 15%, given by packages that are too bulky or heavy to be managed by this Pharmathek robot model, is stored in an adjacent area of the hospital.

The automated grippers have the task of placing the references among the hundreds of shelves present within the two units as well as picking them up in case of request. In this case, after picking them up, the mechanical gripper inside the robot releases the package near a chute which makes the packages fall back into special baskets. The basket is then slipped over a special roller, ready to be delivered to each specific department.

The inventory is automatically updated in real time.

The Pharmathek robotic warehouse of the “Madre Teresa” Hospital in Schiavonia processes an average of 1,700 packs per day.